Managing production can be simple!

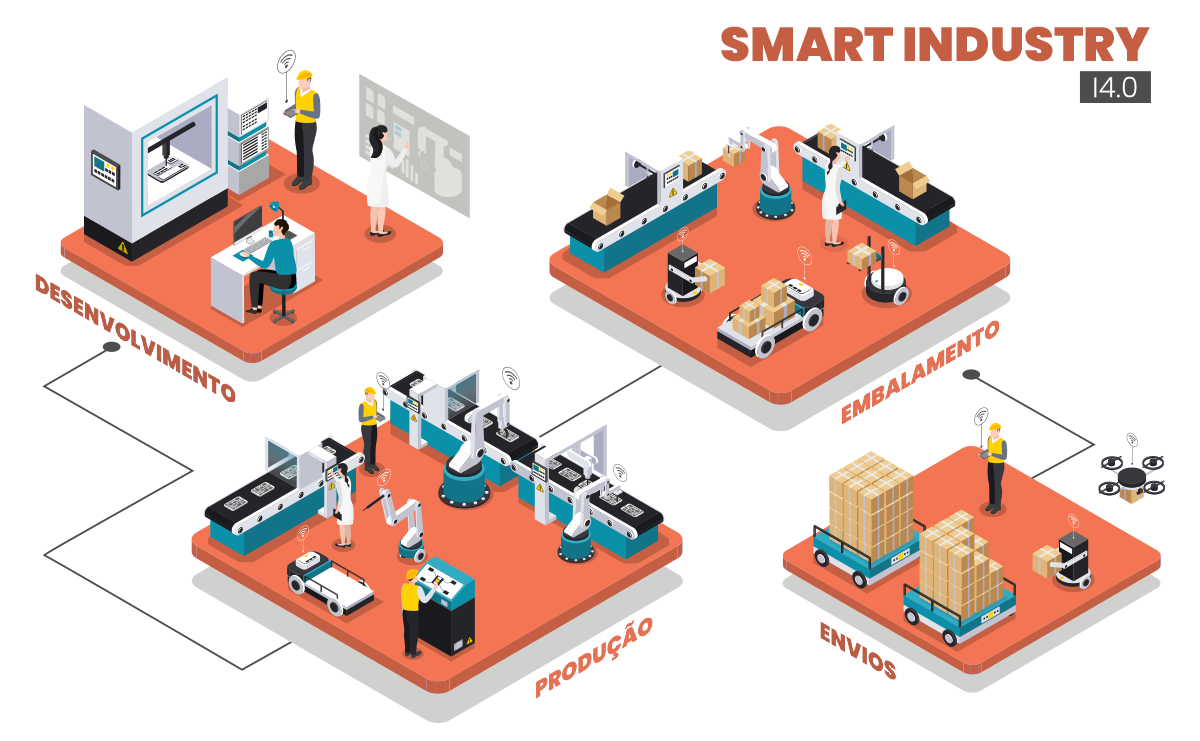

The leap to Industry 4.0 is a step desired by many companies, who want to increase the control of their factory floor to a level comparable to the world's largest industries.

The implementation of visual systems for work organization proved to be an effective and simple way to distribute and organize tasks.

- Facilitate communicative and work processes;

- Facilitate quick access to information;

- Control consumes: time and material;

- Execute schedules and workloads;

- Automatic collection of machine metrics.

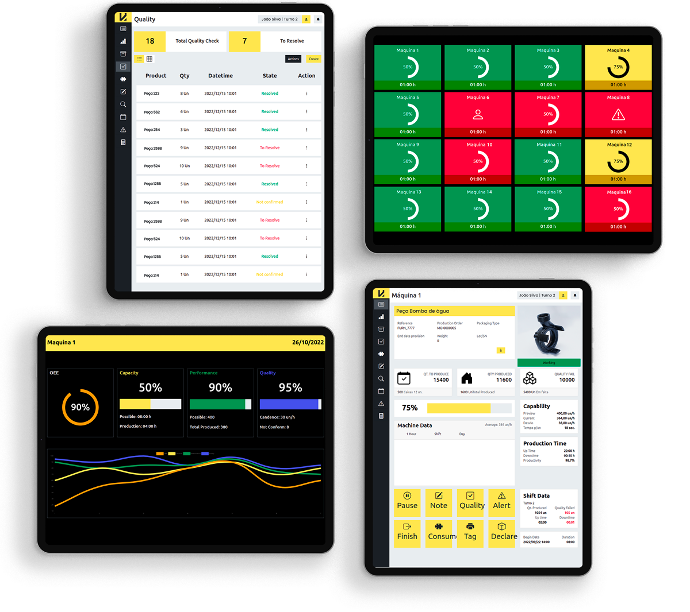

Kiosks

Visualization equipment

To view information such as:

- Production states;

- Daily production goals;

- Stocks;

- Shipments/Receipts;

- Packing;

- Material order alerts.

- ...

Dashboards

Interaction equipment

To enter information such as:

- Start/Pause/End of production;

- Production declaration;

- Choose the item to produce;

- Call supervisor;

- Print reports and labels;

- Work instructions;

- ...

Software

Able to help productive processes in a simple and effective way, where the priority of “user experience” is given.

- Equipment management;

- Order management;

- View orders;

- Performance view.

- ...

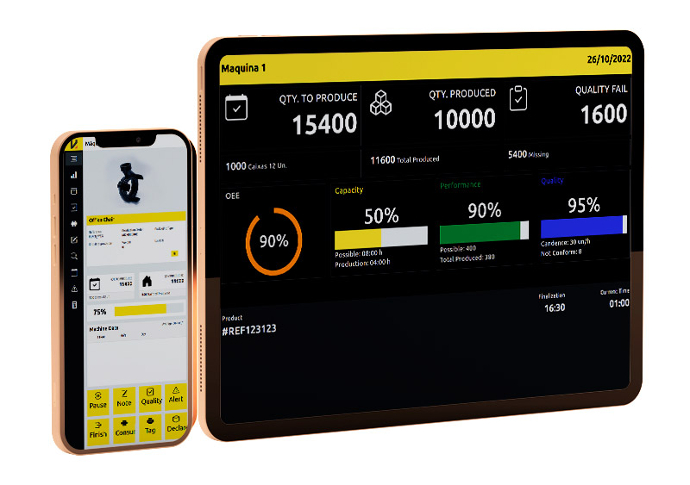

KIOSKS AND DASHBOARDS ON THE FACTORY FLOOR

Placement of monitors and kioskes on the factory floor.

For visualization or interaction. They serve to monitor, report and obtain data on each section, machine and operator.

PRODUCTION PREPARATION AND PLANNING

From purchase to shipment of the order.

Manage and plan all phases of the project.

Planning of all phases of the project, load of machines, allocation of human resources, analysis of installed capacities, time management, etc.

MULTI-PLATFORM SOLUTION

Software developed in the cloud so that it can be used on any device.

Computer, Tablet, Dashboard, Smartphone, etc.

INTEGRATION WITH ERP SOFTWARE

Possibility of integrating with the ERP software implemented in your company.

For connection and cross-referencing of data between all departments.

MACHINES DATA ACQUISITION

To control, monitor and integrate.

With all production information.

INTEGRATED INDUSTRIAL MANAGEMENT

(MES - Manufacturing Execution System)

Software connected to all machines and production lines for process control and optimization.

DEVELOPMENT OF CUSTOMIZED SOLUTIONS

Solution adapted to the reality of the reality of each company.

Industry 4.0 made simple

Factory floor monitoring, analysis and optimization

We want to present you with this solution suited to the reality of your company.